Kikuta niwu*]On-

Measure the refraction online for thehigh

Spinning process of fast melt

Pet)

The optical delay of the running wire is measured using a device containing a rotating bias mirror.

Pay special attention to detailed measurements near the neck --Like deformation.

Through measurements during shooting

The rising speed of 5 km/min is about 1 [ms. sup. -1]

Was investigated.

The relationship between the applied stress and refractive index, tension and temperature distribution of thespin-is analyzed.

Calculate the line according to the diameter profile obtained by the experiment.

Although the strain rate is very high, the linear relationship between the parameters calculated by dividing the stress by temperature and the double refraction is confirmed to maintain a stress/temperature value of about 0.

017 and 10 kPa/K, respectively.

Introduction of heterogeneity is one of the most important properties of polymer materials.

The main source of the heterogeneity is the orientation of the molecular chain.

By controlling molecular orientation, the mechanical, optical and many other properties of polymer products can be improved.

Therefore, it is important to analyze the mechanism of orientation development through the experimental and theoretical study of polymer processing behavior. High-

Rapid melting rotation is a process of significant molecular orientation and orientation

Induced crystals occur.

The fiber structure develops at an extremely high rate of tensile strain, commonly referred to as the neck-

Like deformation.

For on-there have been many attempts

In line measurement thespinning behavior

High-speed melt spinning process]1].

We also measured the diameter and temperature of the spin.

Linepay special attention to areas near the neck-Like deformation.

Through the spin-line ofpoly(

Pet)(PET)

, Detected crystal heat near the neck

Like deformation [2].

The Crystal rate estimated based on this result is [10. sup. 4]-[10. sup. 5]

Several times larger than the homophobic state.

Neck diameter profile-

By analyzing the signal from multiple diameter monitors [4], similar deformation was studied in detail3, 4]

Capture images by using a specially developed optical system and a CCD camera [5].

These analyses confirm the maximum strain rate near the neck

The value of Likedeformation is higher than the month 【ms. sup. -1].

Similar results of temperature and diameter distribution at high temperaturespeed spin-

Haberkorn et al reported production lines for Nylon 6 and nylon 66. [6].

Development of fiber structure

Like deformation also by taking widthangle X-

Light scattering pattern using synchronous radiation light source [7].

Although there are some papers on this

On-Line Measurement of refractive index during hot spinning and solution spinning [8, 9]

, A detailed investigation in neck-

Like deformation has not been reported.

Experimental melt spinning (

Pet)[PET]

Particles provided by TorayIndustries Inc.

Used in this study.

The characteristic viscosity of the polymer is 0. 949 dL/g.

A high molecular weight polymer was selected because of the neck

Like starting from a relatively low cost.

Although the sharpness of the neck increases the speed

Deformation is not so obvious [4].

PET polymers are from single-

The spray hole of 0.

300 in diameter [degrees]C.

The throughput is controlled at 5. 0g/min.

Quenching air is not suitable for spin-line.

The extruded polymer is a high

The speed winding machine is placed 330 cm below thespinneret. The take-

The rising speed ranges from 1 to 5 km/h. Thespin-

Measuring line tension using a tension meter (

Roschild mini lab046).

Tension Measurement of the solidification area of spin-

Line up by changing the distance from the spray head. Theon-

Line measurements of diameter and refractive index were also performed at different positions of the spinline.

The measurement principle described in the next section.

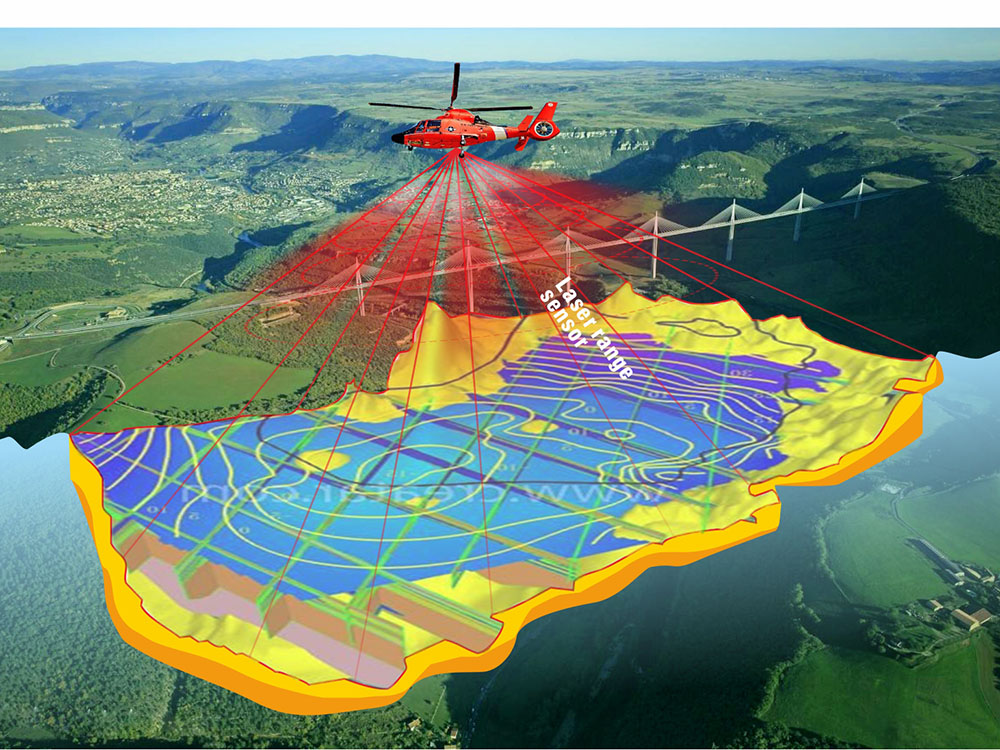

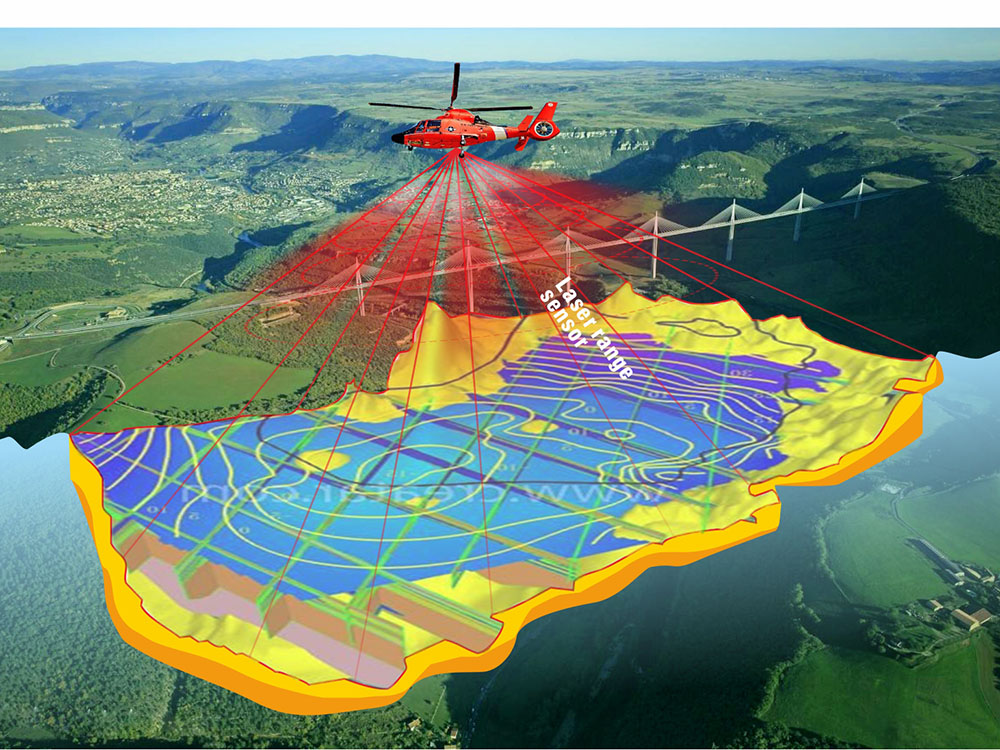

Birefringence measurement principle the schematic diagram of the birefringence measurement system used in this work is shown in the figure1.

The optical system consists of a diameter measuring block and an optical delay measuring block.

For diameter measurement, three diameter monitors (

From thetop, Zimmer OHG model 460A/month, Keyence LX2-

OHG l00, Zimmer Model460A/month)were used.

All diameter displays are based on the back

Lighting principle.

The distance between each diameter is 39mm.

Using multiple diameter monitors allows us to monitor the movement of the position of the neck

Like deformation (3).

Optical systems for measuring delays, similar to those reported in the patent [10]

By one of him-

Nelaser light source, polarization filter, four points-

Wave chips, rotary polarization filters, beam splitters, beam splitters, and photoelectric detectors. Time-

Course changes in reference light intensity [I. sub. ref](t)

The intensity of light runs through the silk [I. sub. meas](t)

Can be expressed as follows (

See attachment for details): [I. sub. ref](t)= A [1 -cos2[phi](t)](1)[I. sub. meas](t)= A {l -cos[2[phi](t)+ [delta]}(2)

Where A is the amplitude of light. [phi](t)

The angle of rotation of the Asian filter, and 【delta]

Optical Delay of optical fiber samples.

Refraction of spinline [delta]

N can be obtained from [delta]

Use the following equation. [delta]

However, it is difficult to determine the position of the third jump, which should exist.

We assume that the current phase is about 0.

27 s is too fast and the detection is not clear because the change in the order from 2 to 3 occurred shortly after the change in 1 to 2.

Figure 1 shows the change of phase shift, diameter and refraction. 8b.

In this figure, the phase offset after considering the interference sequence is shown.

In addition, the horizontal coordinates are multiplied by the time-

Determine the shaft by the movement speed of the neckLike deformation.

Early in the neck-

Like deformation, the refractive index gradually increases with the decrease of the fiber diameter.

As the fiber diameter decreases, the increase in birefringence will accelerate and suddenly stabilize when the steep deformation ends.

As shown in figure shown in

7, there is still a gradual increase in double refraction after the neck

Like deformation.

Analysis of spin temperature and tension distribution

Starting with the measured diameter at a certain position, the continuity equation can be used to evaluate the filament velocity. W = [pi][D. sup. 2]/4 [[rho]. sup. v](8)

Then, the temperature and tension distribution of the spin-

According to the heat balance and momentum balance equation, the line can be analyzed from the diameter and velocity distribution [11]. dT/dx = -[pi]Dh/[WC. sup. p](T -[T. sup. a])(9)dF/dx = W (dV/dx -g/V)+ [pi]D[[tau]. sub. f](10)

Where F, V, D, and T represent spin-

At the line tension, speed, diameter and temperature at the distance of the spray head x, W is the extrusion mass flow rate, h and [[tau]. sub. f]

Heat transfer coefficient and air friction stress ,[rho]and [C. sup. p]

Density and thermal capacity of polymer, acceleration of gravity, and [T. sub. a]

Ambient temperature.

Parameters and empirical equations for calculation, described in detail elsewhere [1]2,12]

, As shown below. [rho]= 1. 356 -5. 0 X [10. sup. -4]T (g/[cm. sup. 3])(11)[C. sup. p]= 1. 26 + 2. 5 X [10. sup. -3]T (J/(g K))(12)h = [K. sub. a]/D (0. 28 [[R. sup. -0. 334]. sub. e])(13)[[tau]. sub. f]= 1/2 [[rho]. sub. a][V. sub. 2](0. 66[R. sup. -0. 61]. sub. e])(14)

Temperature and tension distribution of rotation

According to these equations, the line is estimated based on the measured spinlinetension.

Figure 1 shows the temperature and tension distribution of the analysis and the experimental data9.

As can be seen from this picture, the neck

Deformation like 5 km/h occurs around [[degrees]C.

Relationship between stress, temperature and Birefringence

The law of optics can be derived by comparing the stress source [sigma]

Refractive index n of Gaussian chain [1]13]. n = C[sigma](15)

Pressure here-

The optical coefficient C can be expressed as follows. C = 2[pi]/45kT [(n + 2). sup. 2]/n ([[alpha]. sub. 1]-([[alpha]. sub. 2])(16)

Where n is the homophobic part of the refraction index ,[[alpha]. sub. 1]-[[alpha]. sub. 2]

The difference between the axial and lateral polarization capabilities of the link, the absolute temperature and the boerzman constant.

Relationship between birefringence calculated from the tension and diameter distribution of 1 km/min spin-and tensile stress

The line is shown in Figure 1. 10a.

Considering the temperature dependence of stress

The optical coefficient, the diagram between the refraction, and the parameters calculated by dividing the tensile stress by the spin

As shown in the figure, the line temperature has been reduced. 10b.

The curve in figure 1 has a slight downward bend10a.

On the other hand, the picture.

10b gives a pretty good straight line through the origin.

So log-

The latter type of pair graph is prepared from the total diameter of the various bands and the profile of the double refraction

Speed as shown in the figure11.

It can be seen from this figure that the refraction and stress/temperature have a good linear relationship with the slope until these values are about 0.

017 and 10 kPa/K, respectively.

Month of amorphous Ifintrinsic double refraction. Adoption 275 [14]

This critical refraction corresponds to the orientation factor of about 0. 06.

From the intercept of a straight line, the C × t value is 1.

Get 66 K/MPais.

The value corresponds to stress-

Optical Coefficient of 4. 8 [GPa. sup. -1]

Very consistent with the reported value [at glass transition temperature]15].

Above this area, there was a sharp increase in refraction depending on the shooting, followed by a different degree of saturation trendup velocity.

A similar analysis of the data obtained near the neck

Deformation as shown in the figure12.

In the figure, the data from the overall rotation

The line was also drawn.

These two data have good continuity.

In addition, it was found that the linear relationship between the double refraction and the stress/temperature remained at about 0 of the double refraction. 02.

Smooth profile of diameter, strain rate and stress/temperature near the neck-

Deformation as shown in the figure. 13.

A position on the neck-

As shown in the figure, the deformation corresponding to the critical stress/temperature value.

It should be noted that pressure-

Even if the strain rate is as high as ca, the law of optics applies to the critical refraction. 0. 5[ms. sup. -1]

Temperature is about 170 [degrees]C.

Conclusion an optical system for measuring fiber diameter and delay at the same time is developed.

Using this system, in-

High quality of Linemeasurement refraction

The rapid melt spinning process was completed.

It is also possible to measure the detailed polarization profile near the neck

Like deformation, the measurement at the time of shooting

The rise rate of 5 km/min provides polarization development data at strain rates up to 1 [or so]ms. sup. -1].

Temperature and tension distribution of spin

Calculate the line according to the diameter profile obtained by the experiment.

These profiles are used to analyze the relationship between the applied tensile stress and the refractive index.

Although the strain rate is very high, a linear relationship between the refraction and the stress/temperature is determined to maintain a value of about 0.

017 and 10 kPa/K, respectively.

Appendix detailed arrangement of optical system measuring delay (phase shift)

As shown in the figure. 14.

Line polarized laser becomes circular polarized light after passing through aquarter-

The wave plate then changes to a rotational linear polarized light by rotating the polarization filter.

Electrical vector components in the direction of X and y ,[E. sub. x]and [E. sub. y]

Because light [E. sub. x]= Asin[phi](t)sin[omega]t (17)[E. sub. y]= Acos[phi](t)sin[omega]t (18)

Where A is the amplitude ,[omega]

Angle frequency, and [omega](t)

Rotation angle of the polarized filter.

Time average intensity of reference light [I. sub. ref](t)

Can be expressed as follows. [I. sub. ref](t)= [[E. sup. 2]. sub. x]=([A. sup. 2]/2)[sin. sup. 2][phi](t)= ([A. sup. 2]/4)[1-cos2[phi](t)](19)

On the other hand, by measuring light after the quarter-wave plate is [E. sub. x]= Asin[phi]sin ([omega]t + [pi]/2)= Asin[pi]cos[omega]t(20)[E. sub. y]= Asin[phi]sin[omega]t (21)

Therefore, the electrical vector component perpendicular to the fiber axis in the direction ,[E. sub. [alpha]]and[E. sub. [beta]], are [E. sub. [alpha]]= [(E. sub. x]-[E. sub. y])/[square root of]2 = -(A/[square root of]2)sin[[omega]t -[phi](t)](22)[E. sub. [beta]]= [(E. sub. x]+ [E. sub. y])/[square root of]2 =(A/[square root of]2)sin[[omega]t + [phi](t)](23)

Since the directional PET fiber has a higher refractive index in the direction parallel to the fiber axis, the light after passing through the fiber can be expressed as follows. [E. sub. [alpha]]= -(A/[square root of]2)sin [[omega]t -[phi](t)-[delta]](24)[E. sub. [beta]= (A/[square root of]2)sin [[omega]t + [phi](t)](25)where [delta]

Optical Delay. Therefore, [E. sub. x]

The component on the photo detector is [E. sub. x]([E. sub. [alpha]]+ [E. sub. [beta]])/[square root of]2 = -Acos ([omega]t -[delta]/2)sin [-[phi](t)-[delta]/2](26)

Therefore, the time average intensity of the measured light [I. sub. meas](t)is [I. sub. meas](t)= [[E. sup. 2]. sub. x]= ([A. sup. 2]/2)[sin. sup. 2][[phi](t)+ [delta]/2]= ([A. sup. 2]/4){1 -cos [2[phi](t)+ [delta]]}(27)

The author hopes to thank Mr. M.

Mr. fuhara andY.

Maeda, TorayIndustries Inc.

Thanks for the help and discussion they provided in this work. (*. )

Who should communicate. REFERENCES (1. )A. Ziabicki and H. Kawai, eds. , High-

High-speed fiber spinning by John Willie & Sons (1985). (2. )T. Kikutani, Y. Kawahara, T. Matsui, A. Takaku, and J. Shijing clear water-Kakou, 1, 333 (1989). (3. )T. Kikutani, T. Matsui, A. Takaku, and J.

Thousand autumn, thousand autumn, 45,441 (1989). (4. )T. Kikutani, N. Ogawa, and N.

Okui, 12 annual meeting of Polymer Processing Association315, Sorrento. Italy (May 27-31, 1996). (5. )T. Kikutani, Y. kawahara, N. Ogawa, and N.

Okui, Mr. igkaixi. 50, 561 (1994). (6. )H. Haberkorn, K. Hahn, H. Breuer, H. -D. Dorrer, and P. Matthles, J. Appl. Polym. Sci. , 47, 1551 (1993). (7. )H. Hirahata, S. Seifert, and H. G.

Polymer mann, Polymer, 5131 (1996). (8. )S. A. Mortimer and A. A.

Leather guy from textile factoryJ. , 64, 544(1994). (9. )F. -M. Lu and J. Spruiell, J. Appl. Polym. Sci. , 34, 1541(1987). (10. )

Japanese patent application 79-1076, P. H. Harris, I. C. I. (1979]. (11. )S. Kase, and T. Matsuo, J. Polym Set. , Part-A, 3, 2541(1965). (12. )J. Shimizu, N. Okui, and T. Kikutani, High-

Fiber spinning speed, p. 179, A. Ziabicki and H. Kawai, eds.

John Willie & Sons1985). (13. )R. G.

Larson, equation of composition of polymer melting and solution, p.

95, Butterworth Publishing House, Stoneham ,(1988). (14. )J. H. Dumbleton, J. Polym. Sci. , A-2, 6, 795 (1968]. (15. )K. Oda, J. L. White, and E. S. Clark, Polym. Eng. Set, 18, 53(1978).